ລາຍລະອຽດດ່ວນ

ເງື່ອນໄຂ: ໃໝ່

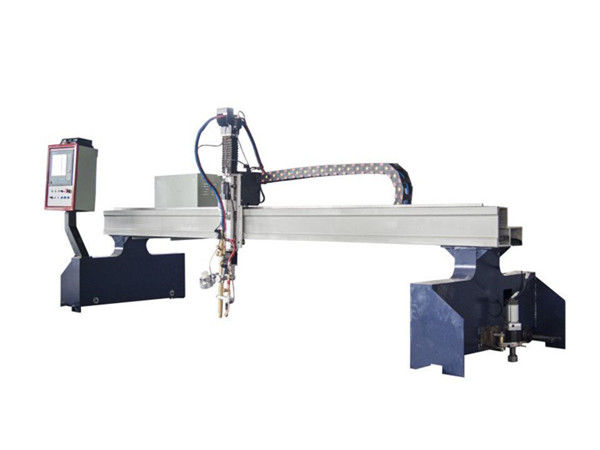

ພະລັງງານທີ່ໃຫ້ຄະແນນ: 7.5kw

ຂະໜາດ (L*W*H): 2100*3200*1600

ນ້ ຳ ໜັກ: 1000KG

ການຢັ້ງຢືນ: CE ISO

ການຮັບປະກັນ: 1 ປີ

ມີການບໍລິການຫລັງການຂາຍ: ວິສະວະກອນທີ່ມີໃຫ້ບໍລິການເຄື່ອງຈັກຢູ່ຕ່າງປະເທດ

ຊື່ຜະລິດຕະພັນ: ເຄື່ອງຕັດໂລຫະ cnc pantograph gantry ຂະຫນາດນ້ອຍ / ເຄື່ອງຕັດ plasma cnc

ສີ: ສາມາດປັບແຕ່ງໄດ້

ວັດສະດຸຕັດ: ວັດສະດຸເຫຼັກກາກບອນສະແຕນເລດ

ຄໍາຮ້ອງສະຫມັກ: ຕັດແຜ່ນໂລຫະ

ໜ້າຈໍ: LCD

ຄວາມໄວຕັດ: 0-8000mm / ນາທີ

ຄວາມຫນາຕັດ: 0-200mm

ການສະຫນອງ Plasma: Jiangsu Jiusheng

ຊອບແວ: STARCAM

ລະບົບ CNC: F2300B

ພາກສ່ວນຕົ້ນຕໍ

1.Beam ໃຊ້ຄູ່ມືເສັ້ນ.

2.Beam adopts ໂຄງສ້າງປ່ອງປະເພດແລະກອບ gantry. ຫຼັງຈາກການເຊື່ອມຕໍ່, ການນໍາໃຊ້ການປິ່ນປົວຄວາມກົດດັນການສັ່ນສະເທືອນເພື່ອບັນເທົາຄວາມກົດດັນທີ່ຍັງເຫຼືອແລະເຮັດໃຫ້ມັນບໍ່ໄດ້ກາຍເປັນການເສຍຮູບພາບ.

ລະບົບສາຍສົ່ງ 3.Mechanical ທັງຫມົດຮັບຮອງເອົາລູກປືນຄວາມແມ່ນຍໍາຂອງລູກປືນແລະຂະບວນການຄວາມຖືກຕ້ອງມາດຕະຖານລະດັບຊາດ 7 meshing ຄວາມແມ່ນຍໍາຂອງເກຍແລະ rack.

ລະບົບ 4.Drive adopts planetary reducer ໂດຍການຮ່ວມມືຈີນ-ເຢຍລະມັນ. ຄວາມຜິດພາດຂອງວັດສະດຸປ້ອນແລະຜົນຜະລິດຂອງມັນພຽງແຕ່ 16 arc.In ໂຄງສ້າງລະບົບສາຍສົ່ງເກຍແນວນອນແລະແນວຕັ້ງເພີ່ມຊ່ອງຫວ່າງການຊົດເຊີຍອັດຕະໂນມັດທີ່ສາມາດເຮັດໃຫ້ໂຄງສ້າງລະບົບສາຍສົ່ງປະຕິບັດຄໍາສັ່ງໂດຍລະບົບ CNC.

5.Main drive beam: ອຸປະກອນຍຶດຕິດທາງລົດໄຟຕາມລວງຍາວຮັບຮອງເອົາໂຄງປະກອບການປະຖົມນິເທດອັດຕະໂນມັດ, ບໍ່ eccentric wheel clamping device.Its ອີງໃສ່ໂຄງສ້າງຄູ່ມືອັດຕະໂນມັດຜົນບັງຄັບໃຊ້ພາກຮຽນ spring ແລະເຮັດໃຫ້ການຍ່າງຫມັ້ນຄົງຢູ່ໃນສອງຄູ່ມືແລະຈະບໍ່ປະກົດວ່າໃກ້ຊິດແລະວ່າງ.

6.ທຸກພາກສ່ວນສະກູແລະເຫຼັກກ້າທັງຫມົດນໍາໃຊ້ຂະບວນການຊຸບສີດໍາຫຼື chrome.

ພາລາມິເຕີທາງວິຊາການ

ບໍ່ | ລາຍການ | ມູນຄ່າ | ໜ່ວຍ |

1 | ໄລຍະທາງຂອງຄູ່ມື | 3000 | ມມ |

2 | ຄວາມກວ້າງຕັດທີ່ມີປະສິດຕິຜົນ | 2500 | ມມ |

3 | ຄວາມຍາວຂອງທາງລົດໄຟຄູ່ມື | 8000 | ມມ |

4 | ຄວາມຍາວຂອງການຕັດທີ່ມີປະສິດທິພາບ | 6000 | ມມ |

5 | ຄວາມຫນາຕັດ Plasma | ເຫຼັກກາກບອນແມ່ນ ≤6 | ມມ |

6 | Torch ຂຶ້ນແລະລົງຄວາມສູງ | ≤150 | ມມ |

7 | ຄວາມໄວຕັດ | 50-3500 | ມມ / ນາທີ |

8 | ລະບົບຂັບເຄື່ອນ | ມໍເຕີມໍເຕີ | |

9 | ຊອບແວຮັງ | STARCAM |

ຄຸນລັກສະນະ

1. rigidity ດີ, ຄວາມແມ່ນຍໍາສູງ. VSR ເພື່ອຮັບມືກັບຄວາມກົດດັນ.

2. ໂຄງສ້າງການເຊື່ອມໂລຫະແຜ່ນເຫຼັກ, ອຸນຫະພູມສູງ quenching, ຮັບປະກັນຊີວິດຂອງເຄື່ອງຈັກ.

3. ຂັບຕັ້ງແລະແນວນອນ.

4.Domestic stepper drive (ລະບົບຂັບນໍາເຂົ້າສໍາລັບທາງເລືອກ).

5. ລະບົບການຂຽນໂປລແກລມອັດຕະໂນມັດ, ເຊິ່ງເປັນຕົວຢ່າງແລະງ່າຍຕໍ່ການເຮັດວຽກ.

6. ການຄວບຄຸມ CNC.

7. ຊອບແວຮັງ CAM.