ຂໍ້ມູນພື້ນຖານ

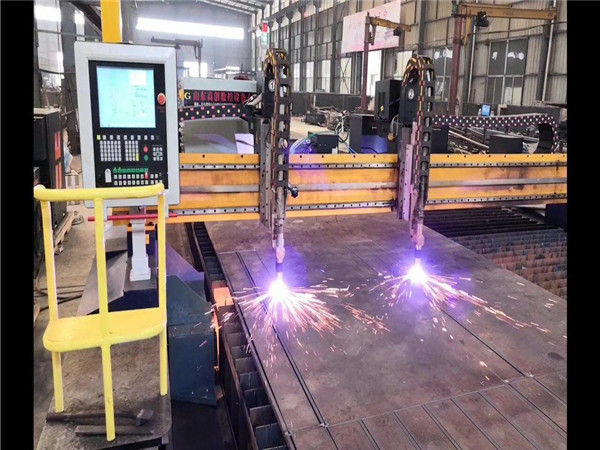

ໝາຍເລກຮູບແບບ: SM-D1325

ຊື່: ເຄື່ອງຕັດ Plasma

ເງື່ອນໄຂ: ໃໝ່

ລະບົບການຄວບຄຸມ: Starfire ຫຼື Start

ສາຍສົ່ງທາງລົດໄຟ: ໄຕ້ຫວັນ Hiwin ຫຼື Abba

ຄວາມຫນາຂອງການຕັດ: 0-50mm

ແຮງດັນ: 220V ສໍາລັບເຄື່ອງຈັກ, 380V ສໍາລັບພະລັງງານ Plasma

ຄວາມໄວຕັດ: 0--8000mm / ນາທີ

ປະເພດເຄື່ອງຈັກ: Portable Type

ຄວາມກວ້າງແຖວຕໍ່າສຸດ: 0.1nm

ການຮັບປະກັນ: 12 ເດືອນ

ການຫຸ້ມຫໍ່ການຂົນສົ່ງ: ກໍລະນີໄມ້ອັດມາດຕະຖານສົ່ງອອກ

ຂໍ້ມູນຈໍາເພາະ: 1500x3000mm

ພາລາມິເຕີຂອງເຄື່ອງຈັກ

| ຕົວແບບ | 1325 1530 2030 (ເຄື່ອງຕັດ plasma cnc) |

| ພື້ນທີ່ເຮັດວຽກ | 1300x2500mm ຫຼື 1500x3000mm ຫຼື 2000x3000mm |

| ໂຕະເຮັດວຽກ | ຕາຕະລາງແຂ້ວເລື່ອຍ |

| ໂຄງສ້າງເຄື່ອງຈັກ | ຕຽງນອນຂອງເຫຼັກກ້າຊ່ອງ / ຫນ້າທີ່ຫນັກ |

| ລາງລົດໄຟ | ລາງລົດໄຟໄຕ້ຫວັນ Hiwin Square (ທາງເລືອກ ABBA) |

| ມໍເຕີ | Stepper motor ແລະ driver (ທາງເລືອກ Servo) |

| ກັບເຄື່ອງອັດອາກາດ | ເພື່ອເຮັດໃຫ້ຫົວຕັດເຢັນ, ລະເບີດອອກ slag |

| ຄວາມໄວຕັດ | 15-20m / ນາທີ |

| ຄວາມຫນາຕັດ | ຂຶ້ນກັບປະຈຸບັນຂອງແຫຼ່ງພະລັງງານ plasma |

| ການສະ ໜອງ ພະລັງງານ | Huayuan Power (USA Hypertherm ສໍາລັບທາງເລືອກ) 63A 100A160A 200A |

| ລະບົບຄວບຄຸມ | STAFIRE ຫຼືເລີ່ມຕົ້ນ |

| ຊອບແວ | Fastcam / Artcam / ປະເພດ 3 |

| ແຜ່ນເຫຼັກເຫັນແຂ້ວ mesa | Ray plug drives 860 |

| ຮູບແບບການເຮັດວຽກ | arc ບໍ່ຕິດຕໍ່ |

| ອັດໂນມັດຕີເສັ້ນໂຄ້ງ | ການປະຕິບັດທີ່ຫມັ້ນຄົງ, ພົ້ນເດັ່ນຂື້ນແມ່ນອັດຕາຜົນສໍາເລັດສູງກວ່າ 99%. |

| ເຮັດໃຫ້ຄວາມຖືກຕ້ອງ ຕຳ ແໜ່ງ ຊ້ ຳ ຄືນ | ± 0.05mm |

| ຄວາມແມ່ນຍໍາຂະບວນການ | ± 0.3mm |

| ຮູບແບບການໂອນໄຟລ໌ | ອິນເຕີເຟດ USB |

| ແຮງດັນຂາເຂົ້າ | 3 ໄລຍະ 380V ສໍາລັບແຫຼ່ງພະລັງງານ, 220V ສໍາລັບເຄື່ອງ |

| ການຫຸ້ມຫໍ່ | ການຫຸ້ມຫໍ່ກໍລະນີໄມ້ອັດມາດຕະຖານສາກົນ. |

| ຂະ ໜາດ ເຄື່ອງ | 3520x2320x1340ມມ (ເປັນ 1325) |

ຂໍ້ດີ

1 Gantry ແລະກ່ອງໂຄງສ້າງການເຊື່ອມໂລຫະ, annealed, ຊີວິດການບໍລິການຍາວ, ສະຫມໍ່າສະເຫມີແລະທົນທານພາຍໃຕ້ການໂຫຼດຫນັກແລະສະພາບວົງຈອນຫນ້າທີ່ສູງ.

2 Gap ຫນ້ອຍ gearing transmission, ຄວາມຫມັ້ນຄົງແລະກ້ຽງແລ່ນຢູ່ໃນຄວາມໄວສູງ, ດັ່ງນັ້ນພວກເຮົາສາມາດບັນລຸຄຸນນະພາບການຕັດທີ່ດີເລີດ.

3 ເຄື່ອງເຜົາໄຫມ້ອັດຕະໂນມັດແບບປະສົມປະສານກັບເຄື່ອງຄວບຄຸມຄວາມສູງອັດຕະໂນມັດ, ຮັກສາຄວາມສູງທີ່ເຫມາະສົມລະຫວ່າງໄຟຕັດແລະຊິ້ນວຽກ, ດັ່ງນັ້ນພວກເຮົາສາມາດບັນລຸຄຸນນະພາບການຕັດທີ່ດີທີ່ສຸດ.

4 ສາມາດຕັດຊິ້ນວຽກທີ່ມີ torches ຫຼາຍໃນເວລາດຽວກັນ, ສາມາດປັບປຸງປະສິດທິພາບການຕັດ

5 ການນໍາໃຊ້ຕ່ໍາແລະການບໍາລຸງຮັກສາຄ່າໃຊ້ຈ່າຍ, dispensing ບໍາລຸງຮັກສາພິເສດ, ການໂຕ້ຕອບຜູ້ປະຕິບັດງານເປັນມິດ, ງ່າຍທີ່ຈະຮຽນຮູ້

6 ລະບົບ CNC ທີ່ເຊື່ອຖືໄດ້, ປອດໄພ, ການຂຽນໂປລແກລມອັດຕະໂນມັດ, ການເພີ່ມປະສິດທິພາບຂອງຮັງແລະເສັ້ນທາງການເຈາະ, ດັ່ງນັ້ນພວກເຮົາສາມາດປະຫຍັດເຫຼັກໄດ້ຢ່າງມີປະສິດທິພາບ.

ຫຼັງຈາກການບໍລິການ

1.1 ການຮັບປະກັນຄຸນນະພາບປີ, ເຄື່ອງທີ່ມີພາກສ່ວນຕົ້ນຕໍ (ບໍ່ລວມທັງອຸປະກອນການ) ຈະໄດ້ຮັບການປ່ຽນແປງ

ບໍ່ເສຍຄ່າຖ້າມີບັນຫາໃດໆໃນໄລຍະເວລາຮັບປະກັນ.

2.Lifetime ບໍາລຸງຮັກສາໂດຍບໍ່ເສຍຄ່າ.

3.ຫຼັກສູດການຝຶກອົບຮົມຟຣີທີ່ໂຮງງານຂອງພວກເຮົາ.

4. ພວກເຮົາຈະສະຫນອງຊິ້ນສ່ວນທີ່ບໍລິໂພກໃນລາຄາຕົວແທນໃນເວລາທີ່ທ່ານຕ້ອງການທົດແທນ.

5.24 ຊົ່ວໂມງໃນການບໍລິການສາຍໃນແຕ່ລະມື້, ສະຫນັບສະຫນູນດ້ານວິຊາການຟຣີ.

6. ເຄື່ອງໄດ້ຖືກປັບກ່ອນທີ່ຈະຈັດສົ່ງ.

7.Our ພະນັກງານສາມາດຖືກສົ່ງໄປຫາບໍລິສັດຂອງທ່ານເພື່ອຕິດຕັ້ງຫຼືປັບຖ້າຈໍາເປັນ.